- Mobile Dewatering

- Compact Sewage Treatment

- Dyeing& Printing Sewage

- Food Industry Sewage

- Livestock Sewage

Office Add:Union Building 11 floor, 8th industrial street, Wuxi, Jiangsu, China

Factory Add:Xibei H-Tech Park Wuxi Jiangsu China

Tel: 0086 138 1256 5699

E-mail: jenny@norsenep.com;sales@norsenep.com

Printing and dyeing wastewater treatment solutions

The quality of printing and dyeing wastewater varies with the types of fibers and processing techniques used, and the pollutant components vary greatly. Printing and dyeing wastewater generally has the characteristics of high concentration of pollutants, many types, containing toxic and harmful components, and high chroma. Generally, the pH value of printing and dyeing wastewater is 6~10, CODCr is 400~1000mg/L, BOD5 is 100~400mg/L, SS is 100~200mg/L, and chromaticity is 100~400 times.

Printing and dyeing wastewater treatment equipment

However, when the printing and dyeing process, the types of fibers used and the processing technology change, the wastewater quality will change significantly. In recent years, due to the development of chemical fiber fabrics, the rise of imitated silk and the advancement of printing and dyeing finishing technology, PVA slurry, rayon alkali hydrolyzate (mainly phthalic acid), new additives and other difficult-to-biodegrade organic substances Into the printing and dyeing wastewater in large quantities, its CODCr concentration has increased from the original hundreds of mg/L to more than 2000~3000mg/L, BOD5 increased to more than 800mg/L, and the pH value reached 11.5~12, thus making the original biological treatment system The removal rate of CODCr has dropped from 70% to about 50%, or even lower.

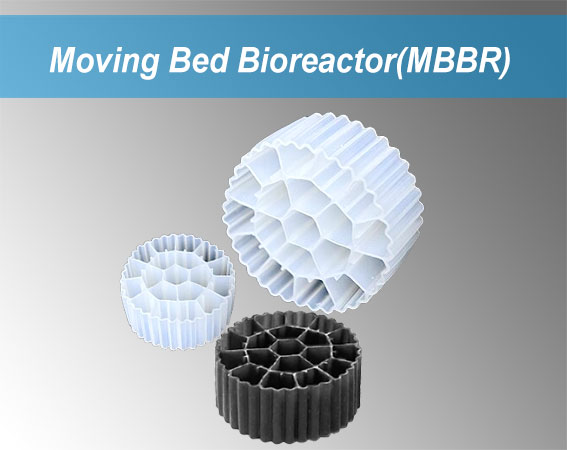

Printing and dyeing wastewater treatment equipment uses the life activities of anaerobic bacteria and aerobic bacteria to consume the organic pollutants in the wastewater. At the same time, the biological flocs formed by microorganisms destabilize and flocculate suspended and colloidal organic pollutants and adsorb them on the activated sludge. The surface degrades organic matter and finally achieves the effect of purifying wastewater.

The printing and dyeing wastewater treatment equipment is equipped with underwater aeration, which is promoted by water flow to form dual-function aeration. When treating waste water, the waste water flows into the aeration zone from the top of the device, and the aerator aerates underwater and pushes the flow to agitate the waste water. The incoming waste water is quickly mixed with the original mixed liquid to the greatest extent to adapt to changes in the quality of the influent water.

The aerator uses the dual functions of water flow and underwater aeration to make the waste water in the aeration zone circulate regularly and increase the dissolved oxygen content in the waste water.

As wastewater flows continuously in the aeration zone, the water quality at all points in the zone is relatively uniform, and the number and nature of microorganisms are basically the same. Therefore, the working conditions of all parts of the aeration zone are almost the same. This will control the entire biochemical reaction under the same good conditions. Organic matter is gradually degraded by microorganisms, and wastewater is purified.

The printing and dyeing wastewater treatment equipment has high purification efficiency, and the various indicators of the effluent meet the national emission standards of the National Pollutant Discharge Standard for Textile Dyeing and Finishing Industry (GB 4267-92). It can also be further equipped according to customer requirements for advanced treatment of strong ozone oxidation to meet the "Urban Wastewater Recycling Landscape Environmental Water Quality Standard" (GB/T 18921-2002) standard for recycling.

Printing and dyeing wastewater treatment equipment process characteristics

1. The biological contact oxidation treatment process is smaller than the activated sludge tank, has strong adaptability to water quality, good impact load resistance, stable effluent water quality, and no sludge expansion;

2. The filler has a large specific surface area, which is easy for microorganisms to hang on and remove the film. Under the same organic matter load condition, the removal rate of organic matter is high, stable and reliable, and there is no need to add chemicals, which saves subsequent costs and reduces operating costs;

3. Hydrolytic acidification can effectively reduce the chromaticity of wastewater, improve the biodegradability of wastewater, reduce the subsequent processing load, and add decolorizing agents for the later period to greatly reduce the amount and save investment;

4. The sedimentation effect is ideal, and better effluent water quality can be obtained;

5. Decolorization treatment, the decolorization rate is over 99.4%, reaching the chromaticity emission standard;

6. Properly dispose of the remaining sludge to ensure the stable and reliable operation of the system, convenient sludge discharge, and reduce manual operations;

7. Adopt a unique construction method to minimize the spread of odor;

8. The operation management is simple, and the operation status can be adjusted according to the actual situation to obtain the best operation effect;

9. High purification efficiency, BOD removal rate is 85% to 90%, chroma removal rate is over 99%, and various indicators of effluent reach the national secondary or primary discharge standards;

10. Able to treat wastewater from the printing and dyeing industry and similar industrial organic wastewater.