- Multi-Disc Screw Press

- Dissolved Air Flotation

- Pretreatment Screens

- Lamella Clarifier

- Sludge Treatment

- Aeration

- MBBR

Office Add:Union Building 11 floor, 8th industrial street, Wuxi, Jiangsu, China

Factory Add:Xibei H-Tech Park Wuxi Jiangsu China

Tel: 0086 138 1256 5699

E-mail: jenny@norsenep.com;sales@norsenep.com

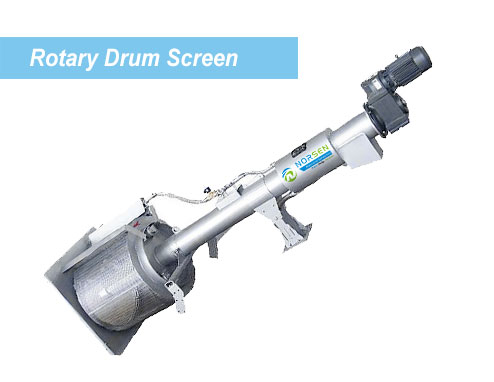

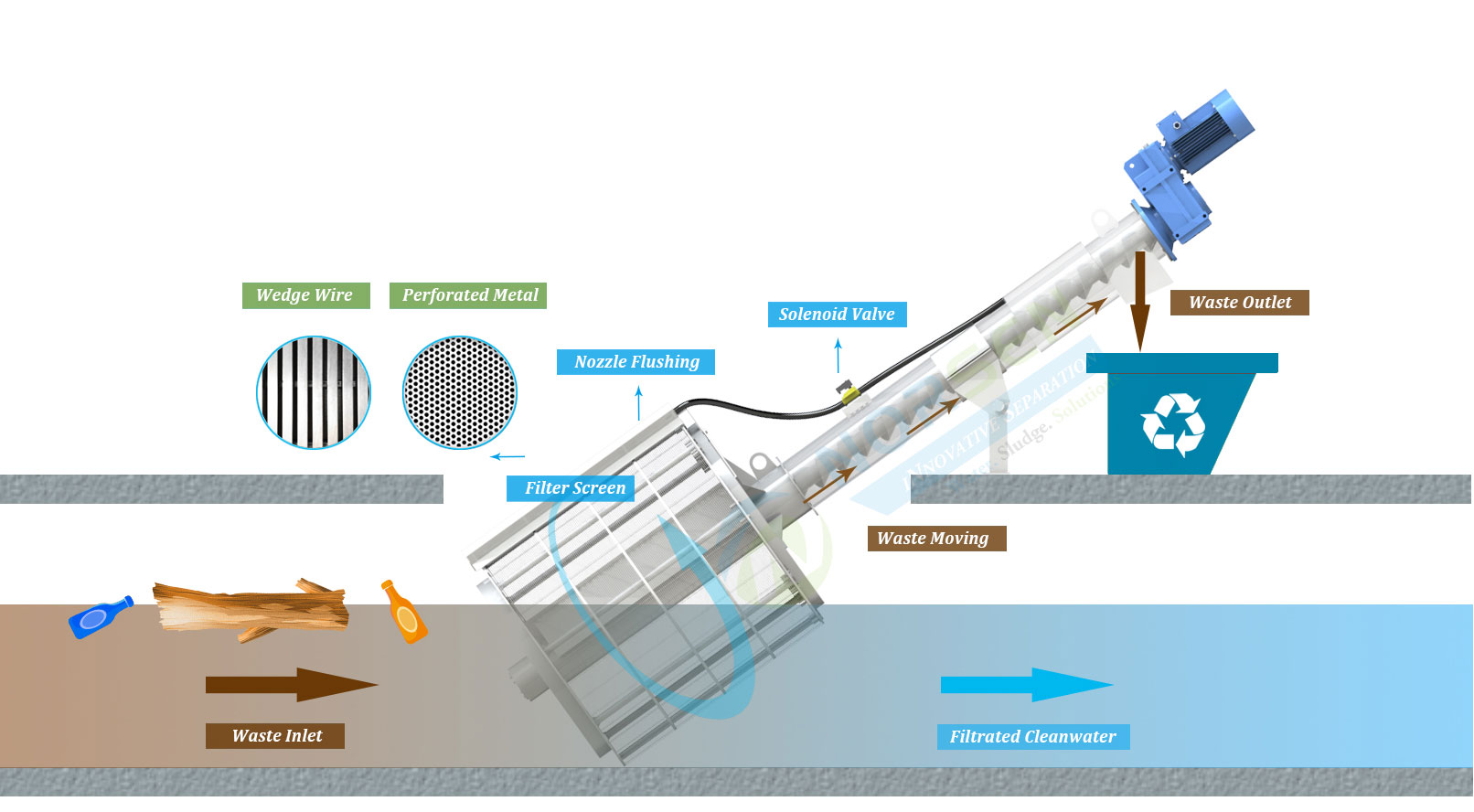

Rotary Drum Screen

ROTARY SCREEN is used for solid/liquid separation for high flow rate and combine two operations: filtration and compacting. They feature a screen basket, perforated pores or wedge wire, that act as a filter and rotating with the transport screw, followed by the transportation that ends with a compacting modulus. Screenings are conveyed by a shaft screw until the compacting/dewatering section where both volume and weight are reduced (up to 40%).

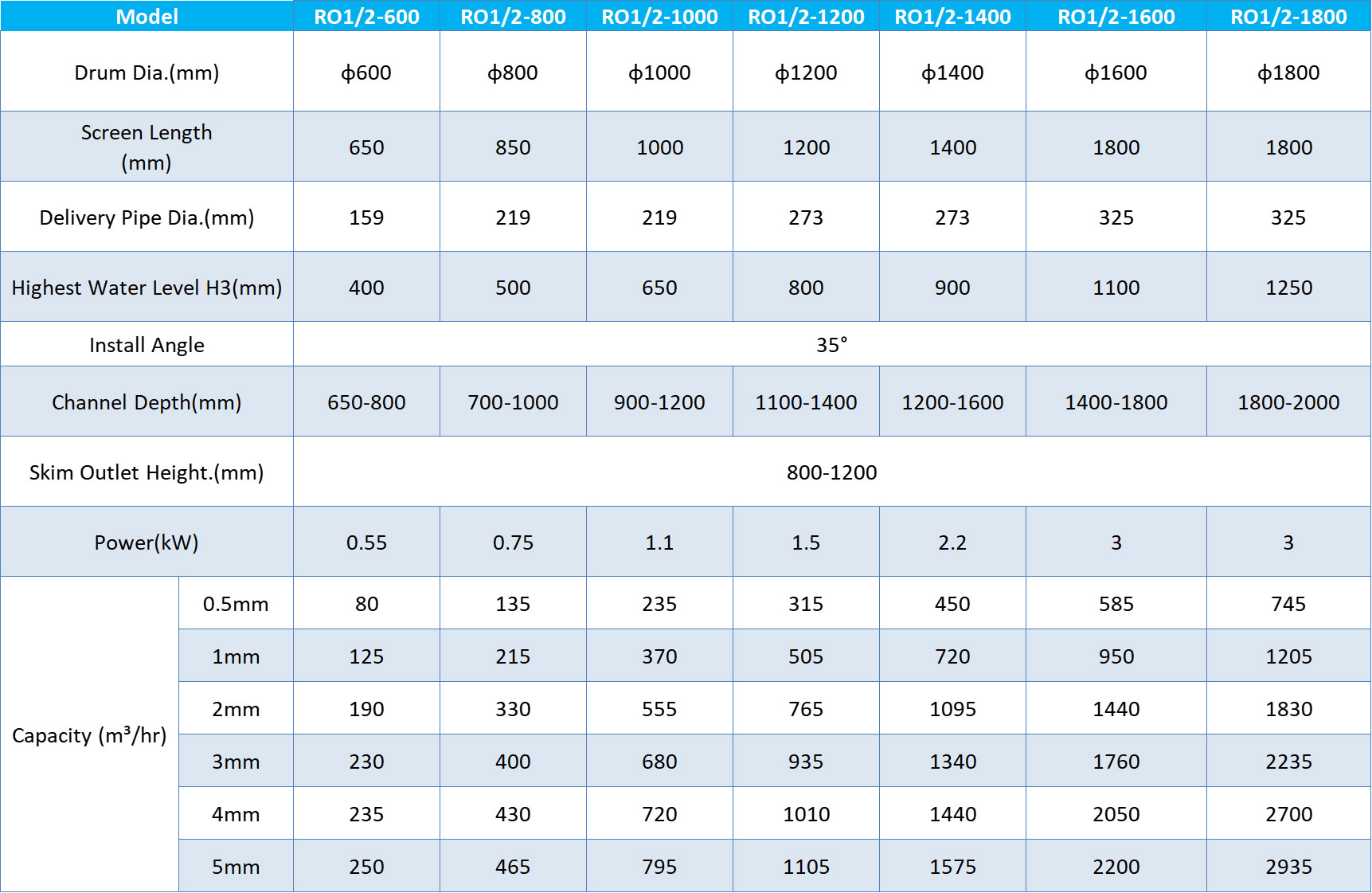

*The different Rotary Drum Fine Screen has Perforated Plate or Wedge-wire models, from 0.5mm-12mm, more models are available to make custom-design equipment, contact our reps. for more details.

■ Low headloss – High separation efficiency

Due to the drum's shape and 35° installation the screen area is much larger than that of a vertical or steeply inclined screen, which results in a low headloss, high separation efficiency and maximum throughput.

■ No by-passing

The entire flow enters the screen drum through its open front end and can only leave the drum through its screen area. This prevents plant overflow and guarantees that the screenings are always retained within the screen drum.

■ Several functions combined in one system

Perform the functions of screenings removal, transport, washing, dewatering and compaction in a single space saving unit.

■ Retrofitting

The design of the RO Screens allows for later modification so that the systems can be adapted to changing requirements. The heating and/or integrated screenings washing can be retrofitted. The bar spacing can also be reduced to meet more stringent requirements.

■ Low maintenance

No lubrication. Regular checking and visual inspection are sufficient.

-

-

Ideal protection for membrane tanks

MORE > -

Pretreatment Screen for varies industries

MORE >