- Multi-Disc Screw Press

- Dissolved Air Flotation

- Pretreatment Screens

- Lamella Clarifier

- Sludge Treatment

- Aeration

- MBBR

Office Add:Union Building 11 floor, 8th industrial street, Wuxi, Jiangsu, China

Factory Add:Xibei H-Tech Park Wuxi Jiangsu China

Tel: 0086 138 1256 5699

E-mail: jenny@norsenep.com;sales@norsenep.com

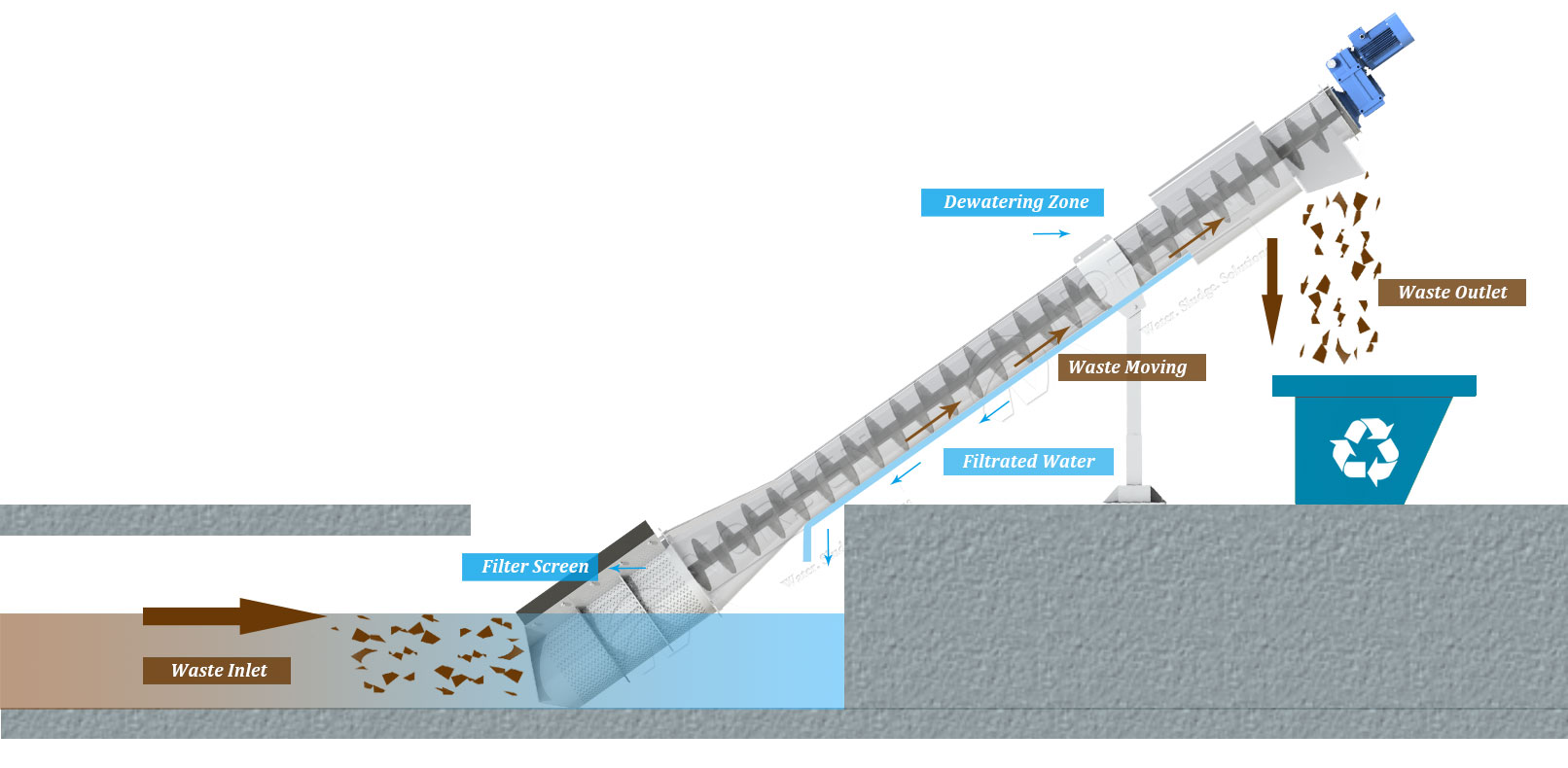

Screw Screen

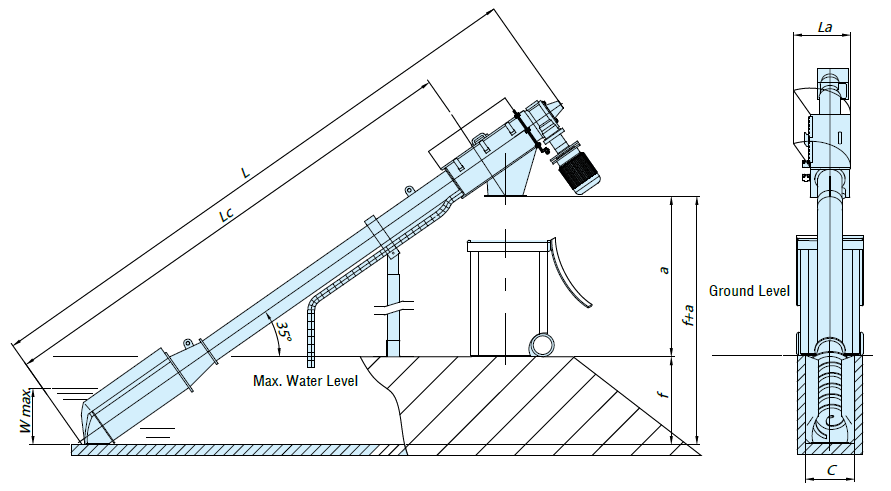

SCREW SCREEN is installed directly in a channel or into a separate tank. The wastewater flows in through the open front end of the screen basket and through the screen bars or perforations. Solids are retained by the screen basket, whereby the separation of floating, settling and suspended solids is dependent upon the screen bar spacing or perforation size.

Blinding of the screen surface generates an additional filtering effect so that solids can be retained that are smaller than the bar spacing or perforation.

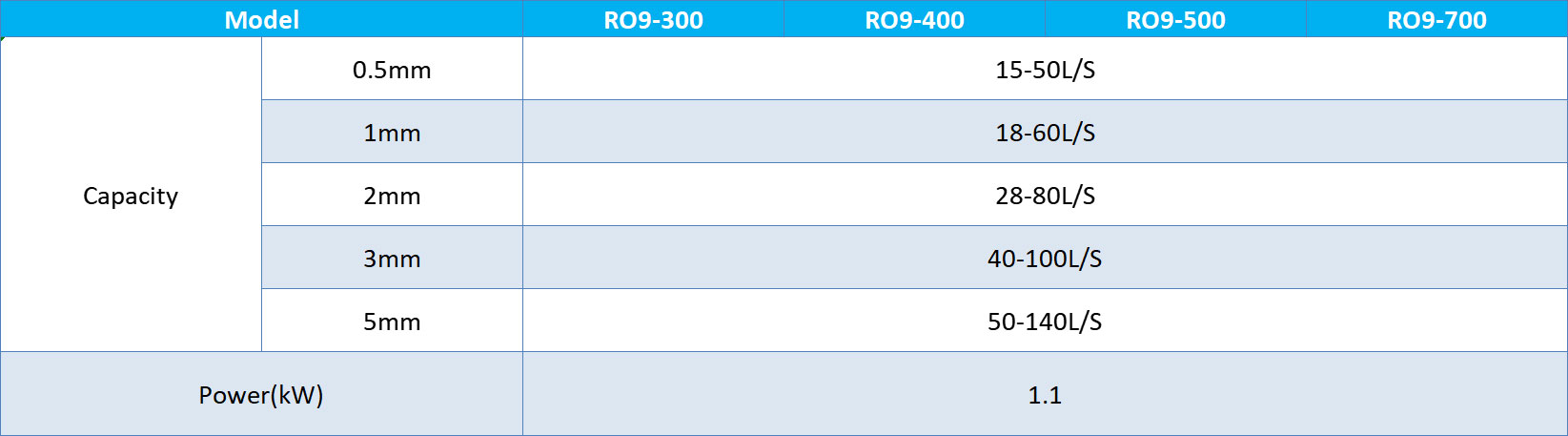

Operation is based upon a unique system that allows combination of screening, washing, transport, compaction and dewatering in a single unit. Depending on the screen bar spacing or perforation and screen size (up to 700 mm screen basket diameter), the throughput can be individually adjusted to specific site requirements. The main advantages of these models of machines are mainly the low cost of initial investment and the subsequent little maintenance required.

■ Low cost solution

■ Excellent performance with fibrous or long wipes

■ Spire in carbon steel, stainless steel 304 or 316L

■ Low maintenance

■ Optional frost-protected unit for outdoor installation

-

-

Ideal protection for membrane tanks

MORE > -

Pretreatment Screen for varies industries

MORE >