- Multi-Disc Screw Press

- Dissolved Air Flotation

- Pretreatment Screens

- Lamella Clarifier

- Sludge Treatment

- Aeration

- MBBR

Office Add:Union Building 11 floor, 8th industrial street, Wuxi, Jiangsu, China

Factory Add:Xibei H-Tech Park Wuxi Jiangsu China

Tel: 0086 138 1256 5699

E-mail: jenny@norsenep.com;sales@norsenep.com

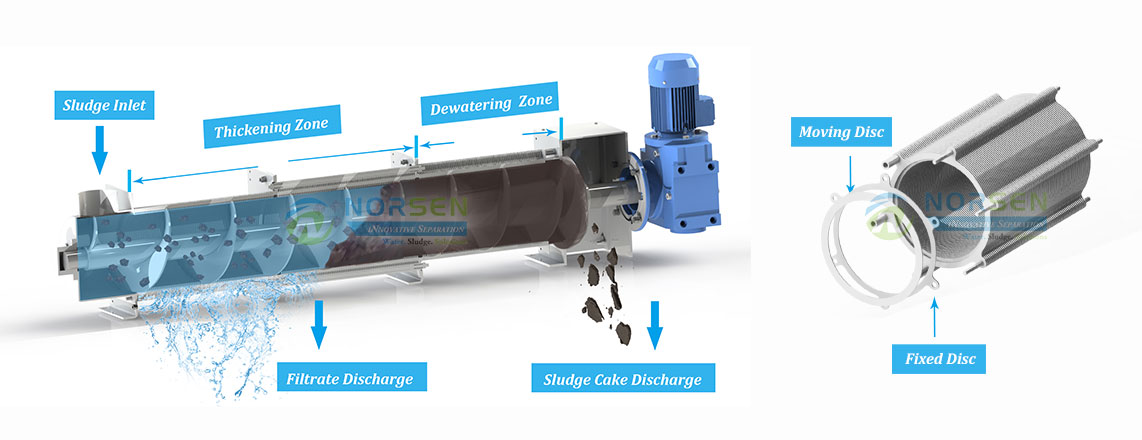

Multi-disc Screw Press

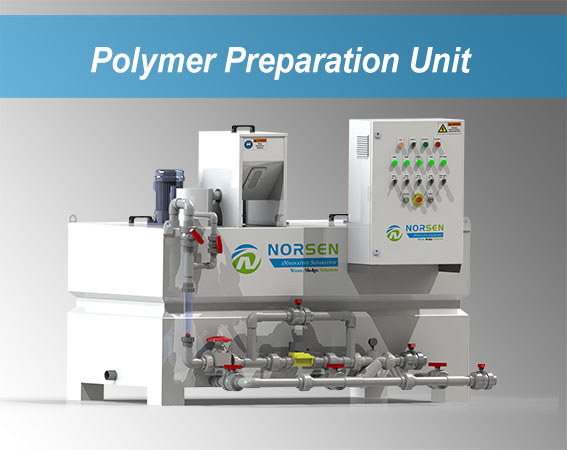

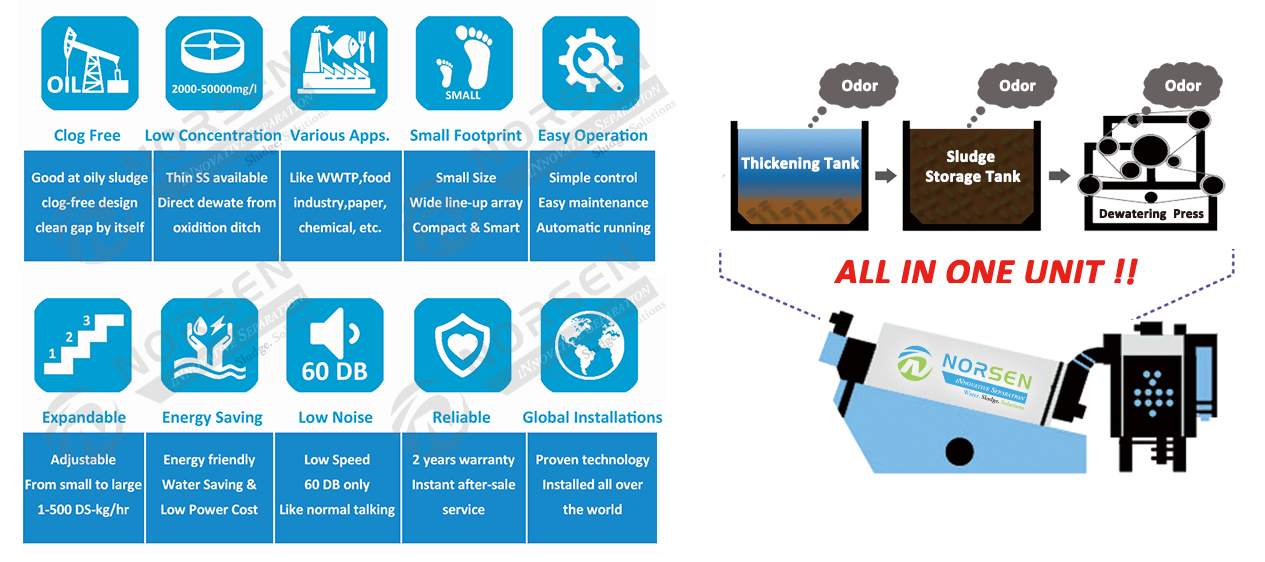

Multi-disc Screw Press Sludge Dewatering Machine, it's clog-free and can reduce the sedimentation tank and sludge thickening tank, saving the cost of sewage plant construction. Using screw and the moving rings to clean itself as clog-free structure, and controlled by the PLC automatically, it's a new technology that can replace the traditional filter press like belt press and frame press, the screw speed is very low, so it cost low power and water consumption in contrast to the centrifuge, it is a cutting edge sludge dewatering machine.

Multi-disc Screw Press Sludge Dewatering Machine is an enclosed high performance sludge dewatering system. It utilizes a central screw auger and a slowly oscillating multi-disc filter to gradually increase pressure on flocculated sludge to produce an exceptionally dry sludge cake. With electrical, water and polymer usage, and high capture rates the system is very cost effective.

Multi-disc Screw Press Sludge Dewatering Machine can be provided with all equipment required for dewatering included and factory mounted, piped and wired on a single stainless steel skid. This equipment includes the sludge pump, wash water pump, polymer dosing system and control panel. The system features fully automated one pushbutton startup and shutdown. Once started up the system can run unattended and can be set to shutdown automatically with no operator intervention.

● Enclosed to minimize odors and noise

● Very low wash water usage(1/8 compared with belt press)

● Very low power consumption(1/20 compared with centrifuge)

● High cake solids

● Minimal operator requirement

● Easy to operate and maintain

● Auto start-up, run and shutdown

● Touch screen operation optional

● Sludge Flow and Cake Monitoring System

● Available with many other options like Dairy, Palm Oil, etc.

* Includes polymer floc tank and mixer system. Multiple options available upon request.

* Single cylinder (ES) models for improved performance and longevity. For modular expansion, add required number of cylinders. With base. One floc tank

recommended for up to 3 cylinders.

* Includes polymer floc tank and mixer system. Multiple options available upon request.

* Single cylinder (ES) models for improved performance and longevity. For modular expansion, add required number of cylinders. With base. One floc tank

recommended for up to 3 cylinders.

- Last Product: N/A

- Next Product:Dissolved Air Flotation

-

-

Low Temperature Sludge Dryer

MORE > -

Sludge Conveyor Machine

MORE >